The latest IPCC report suggests that all pathways to limit global warming to 1.5°C depend on carbon dioxide removal (CDR).¹ There is a suite of CDR technologies that are being put into trial and distribution in order to meet this target, however each with their unique strengths and caveats.

Climate Action Tracker has taken the IPCC models and calculated that even in the best case scenarios with the most progressive climate pledges and policies enacted upon we will not be able to meet the 1.5°C target, and that there is a 19–23 GtCO2/ye at 2030 that CDR needs to fill.² This amount of CO2 cannot be sequestered by any one CDR technology alone due to scaling constraints such as land capacity, policy inertia and logistical complexity, indicating that there is no silver bullet CDR technology to end the climate emergency. The current accepted strategy is to build a diversified portfolio of CDR technologies that can be utilised to combat climate change which hedge risk against each other while also allowing investment into the exploration of a range of groundbreaking solutions.

Mineralisation is one of the CDR technologies that is being investigated. Mineralisation can be split into two main categories:

- In-situ mineralisation: which is the accelerated mineralisation of CO2 in underground reservoirs where CO2 turns into ultramafic rocks.

- Ex-situ mineralisation: which is the above ground weathering and mineralisation of crushed ultramafic rocks on the surface, also known as enhanced rock weathering (ERW).

These CDR technologies share the common chemical mineralisation pathway to effectively sequester CO2. This blog is going to describe what these technologies are, how they work, the benefits and challenges they each have and their involvement in the voluntary carbon market (VCM).

Mineralisation is one of the earth’s natural pathways to transfer CO2 from the atmosphere to the geological carbon cycle, where it is stored in solid stable forms in the Earth’s crust for millions of years. This process occurs through a chemical reaction known as carbonisation, where CO2 reacts with certain types of minerals to form stable carbonate compounds.

In nature, carbonation typically occurs in the presence of water, where CO2 dissolves and reacts with minerals. The most common minerals involved in this process are silicates and carbonates. Silicate minerals, such as olivine and serpentine, contain elements like magnesium and calcium, while carbonate minerals such as limestone and dolomite, contain carbon and oxygen.

The carbonation reaction involves the following steps:

1. Dissolution: Carbon dioxide dissolves in water to form carbonic acid (H2CO3). This acid reacts with the mineral surface, causing it to dissolve and release ions into the water.

2. Ion exchange: The dissolved ions from the mineral surface, such as calcium (Ca2+) and magnesium (Mg2+), react with carbonate ions (CO32-) from the carbonic acid to form carbonate minerals. This process leads to the precipitation of new carbonate compounds.

3. Mineral formation: Over time, the dissolved carbonate ions in the water combine with the released ions to form stable carbonate minerals, such as calcite (CaCO3) or magnesite (MgCO3). These carbonate minerals can persist for millions of years, effectively storing carbon dioxide in a solid form.

The natural process of mineralisation occurs at a relatively slow pace in nature, taking thousands to millions of years for significant amounts of CO2 to be stored. However, in the context of CDR technologies, efforts are made to accelerate this process and enhance the rate of mineral carbonation through various methods like grinding minerals into finer particles or increasing the surface area available for carbonation reactions.

By replicating and accelerating the natural process of mineralisation, CDR technologies aim to harness the capacity of minerals to capture and store carbon dioxide from the atmosphere, contributing to the mitigation of climate change.

In-situ mineralisation is a process of CDR that occurs within natural geological formations, such as underground aquifers or rock formations. It is essentially an acceleration of the natural carbonisation process by pumping CO2 deep into underground geological formations and storing it within the rocks.

The carbon dioxide reacts with minerals that contain calcium, magnesium, or iron and forms stable carbonate minerals, such as calcium carbonate, magnesium carbonate, or iron carbonate, typically within ultramafic rocks. These stable carbonates can remain sequestered for hundreds or even thousands of years, effectively removing carbon dioxide from the atmosphere and storing it in a long-term, stable reservoir.

The process works in this step by step process:

- CO2 Injection: Once a suitable site is identified, carbon dioxide is injected deep underground into the selected rock formations. Injection wells are drilled into the target formation, and CO2 is injected at high pressures to facilitate its migration and dissolution within the rock.

- Dissolution and Transport: The injected CO2 dissolves in the pore spaces of the rock formation, creating a CO2-rich fluid. This fluid migrates through the rock, coming into contact with minerals present in the formation.

- Mineral Carbonation: As the CO2-rich fluid comes into contact with minerals, a chemical reaction called carbonation takes place. The dissolved CO2 reacts with certain minerals, such as basalt or ultramafic rocks, to form stable carbonate minerals. This reaction permanently converts the CO2 into a solid form, effectively storing it within the rock formation.

- Reaction Kinetics and Rate Enhancement: The kinetics of the carbonation reaction can be enhanced through various methods to improve the efficiency of in-situ mineralisation. Techniques such as increasing the surface area of minerals, optimizing temperature and pressure conditions, or introducing catalysts can accelerate the reaction rates and enhance carbonation efficiency.

- Monitoring and Validation: Continuous monitoring and validation techniques are employed to ensure the effectiveness and safety of in-situ mineralisation. This includes monitoring parameters such as pressure, temperature, fluid flow rates, and the quality of the produced carbonates. Monitoring techniques may involve downhole sensors, surface monitoring, or geochemical analysis to assess the progress and stability of the process.

In-situ mineralisation is already in a situation underground where pressure conditions are ideal for mineralisation, therefore the costs can be projected to cost approximately $30/tCO2e³ stored in onland sites. This is especially true if the project is strategically located in areas such as Iceland, which have abundant ultramafic rocks, geothermal energy, and water.

However, MRV of subsurface areas is still a major problem to consider as it requires advanced fluid and geochemical analysis of the subsurface which is quite difficult to perfect. There also needs to be significant government support and upfront investment, given the highly technical and skilled labor needed to make this feasible at scale.

How is in-situ mineralisation different to Carbon Capture and Storage?

It is fairly easy however to get confused between in-situ mineralisation and carbon capture and storage (CCS). They are two different approaches for CDR, but they can be complementary to each other in the context of mitigating climate change.

CCS involves capturing CO2 from industrial sources such as power plants, and then transporting and storing it in geological formations such as depleted oil and gas reservoirs or deep saline formations. CCS is a technology that can reduce the amount of CO2 emissions from large point sources, but it does not remove CO2 from the atmosphere.

In contrast, in-situ mineralisation involves removing CO2 from the atmosphere and storing it in stable mineral forms that are naturally present in geological formations. This process can occur naturally over geological timescales, but it can also be accelerated through various methods such as injecting CO2 into underground formations or enhancing weathering rates of rocks.

The main difference between in-situ mineralisation and CCS is that in-situ mineralisation removes CO2 from the atmosphere and stores it in a stable form within geological formations, whereas CCS focuses on reducing the amount of CO2 emissions from industrial sources and storing it in geological formations. In-situ mineralisation can potentially remove CO2 from the atmosphere on a larger scale than CCS, but it requires identifying and accessing suitable geological formations for mineral storage.

Both in-situ mineralisation and CCS have potential as CDR techniques and can be complementary to each other in the context of mitigating climate change.

Advantages and challenges of in-situ mineralisation

In-situ mineralisation is a promising CDR technology with several advantages, but it also faces several challenges. Here are some of the advantages and challenges of in-situ mineralisation:

Advantages:

- Permanence: Carbon dioxide stored through in-situ mineralisation is permanently sequestered in rock formations, providing long-term carbon storage.

- Natural process: Mineral carbonation is a natural process that occurs over long time scales, and in-situ mineralisation accelerates this process by enhancing the weathering of minerals. This makes it an environmentally friendly and sustainable solution for CDR.

- Co-benefits: In-situ mineralisation can provide co-benefits such as improving soil fertility, reducing acidification, and enhancing biodiversity.

Challenges:

- Scalability: In-situ mineralisation is still in the early stages of development, and scalability remains a challenge. The process requires large quantities of minerals, and the rate of mineral weathering needs to be increased significantly to achieve meaningful CDR.

- Cost: In-situ mineralisation is currently expensive, and cost reduction is critical for the technology’s widespread adoption.

- Site-specific: In-situ mineralisation is site-specific, and not all rock formations are suitable for CO2 storage. The geological conditions need to be carefully evaluated to ensure the safety and effectiveness of the process.

- Monitoring and verification: Monitoring and verifying the effectiveness of in-situ mineralisation is a challenge. The process takes place underground, and the stored carbon dioxide needs to be continuously monitored to ensure it remains permanently sequestered.

In summary, in-situ mineralisation has the potential to provide a long-term and sustainable solution for carbon dioxide removal. However, it faces several challenges, and further research and development are necessary to make the process scalable, cost-effective, and reliable.

Examples of in-situ mineralisation projects around the world

In-situ mineralisation is a relatively new concept for CDR, and there are two examples of in-situ mineralisation projects around the world:

- CarbFix: CarbFix is a project based in Iceland that aims to capture CO2 from a geothermal power plant and inject it into underground basalt formations. The project uses a process called mineral carbonation to store the CO2 as a carbonate mineral within the basalt. The CarbFix project has successfully demonstrated the feasibility of in-situ mineralisation for carbon storage and is now being scaled up to larger volumes of CO2. It works in tandem with an existing hydrothermal power plant. CarbFix has demonstrated that they can completely mineralise a rock deposit in 2 years.

- 44.01: CO2 storage via injection and mineralization in peridotite. Project stores carbon by injecting CO2 in olivine-rich mantle peridotite for geologic storage in mineral form.

These projects demonstrate the potential of in-situ mineralisation as a tool for carbon dioxide removal and storage, but further research and development are needed to scale up the process and make it more cost-effective.

Ex-situ mineralisation involves the extraction of minerals from the ground, the carbonation of these minerals using CO2, and the storage of the resulting carbonates in a controlled environment outside of their natural geological location.

The process involves mining minerals, crushing them into fine particles, and then reacting them with carbon dioxide gas to produce solid carbonates which can be used in construction materials, additives in cement, or crushed and spread on soils and fields to decrease soil alkalinity and potentially feritising the soil.

Here is a step by step explanation:

- Mining and processing minerals: Suitable minerals are mined from the earth and processed to create a fine powder that has a high surface area.

- Carbonation: The mineral powder is then mixed with CO2 gas, which reacts with the minerals to form solid carbonates. This reaction is exothermic, meaning that it releases heat as the CO2 gas reacts with the minerals. The reaction typically occurs under high pressure and elevated temperature conditions to enhance the rate of carbonation.

- Storage and utilisation: The resulting carbonates are then stored in an external environment such as a field or in materials for construction, or deep underground in geological reservoirs.

Ex-situ mineralisation is one of the most expensive CDR technologies costing at around $600/tCO2.

For every 1 tCO2 that needs to be sequestered, 1.6 tonnes of fresh calcium and magnesium rock is required. One option of obtaining this rock is to mine it from the ground and mechanically crush it, which is the most expensive and energy intensive option. Another option is to use existing rock waste, either from industrial processes or from tailings of old mining operations.

Using waste materials this could drastically drop the price to $50/tCO2, however there is only so much waste material available with the most optimistic estimates of 1.3 GT CO2/year. This is only about 10% of what is needed to fill the emissions gap stated by the IPCC.⁴

The other way to offset the costs is to sell the byproducts of mineralisation, but it is unclear if the market is large enough to support CDR technology to make tangible climate impact. For example, the paper manufacturing industry values mineralisation byproducts at prices over $100 per tonne, which could make mineralisation a financially viable industry. The European paper market for lime can sequester about 2m tCO2 annually if replaced entirely with mineralisation byproducts.⁵

This suggests that ex-situ mineralisation has a tangible benefit, but there need to be various innovations within the value chain, whether technological or commercial, that need to be realised to increase its potency and scalability as a CDR technology.

Advantages and challenges of ex-situ mineralisation

Ex-situ mineralisation has several advantages and challenges that should be considered when evaluating its potential as a CDR technology.

Advantages:

- Carbon storage at high scale: Ex-situ mineralisation permanently removes carbon dioxide from the atmosphere by converting it into stable mineral carbonates, and is potentially much more scalable than in-situ mineralisation.

- Use of waste materials: Ex-situ mineralisation can use waste materials as a mineral feedstock, reducing the need for new mining operations and providing a use for waste materials that would otherwise be disposed of.

- Co-benefits: Ex-situ mineralisation can have co-benefits, such as improved construction materials, which can reduce greenhouse gas emissions from the construction industry.

Challenges:

- Energy requirements: Ex-situ mineralisation requires energy to capture and transport carbon dioxide, as well as to react the carbon dioxide with minerals. This energy requirement can lead to increased greenhouse gas emissions if the energy is not obtained from renewable sources.

- Cost: Ex-situ mineralisation can be expensive compared to other CDR technologies, particularly in the early stages of development and deployment.

- Scalability: Ex-situ mineralisation is a relatively new technology, and scaling it up to the level required for significant carbon dioxide removal could be challenging.

Overall, ex-situ mineralisation shows promise as a CDR technology that can permanently remove carbon dioxide from the atmosphere. However, further research and development are necessary to address the challenges and to scale up the technology to the level required for significant carbon dioxide removal.

Examples of ex-situ mineralisation projects around the world

- Mineral Carbonation International (MCI): MCI is an Australian-based company that is developing an ex-situ mineralisation technology for CDR and storage. The process involves using mine tailings, which are waste materials from mining operations, as the mineral feedstock for carbonation. MCI has demonstrated that the technology can be used to produce stable carbonates that can be stored underground or used as construction materials.

- CarbonCure Technologies: CarbonCure is a Canadian-based company that is developing a process for ex-situ mineralisation of carbon dioxide in concrete. The process involves injecting CO2 gas into wet concrete, where it reacts with calcium hydroxide to form calcium carbonate. The resulting concrete has improved strength and durability and can be used in a variety of construction applications.

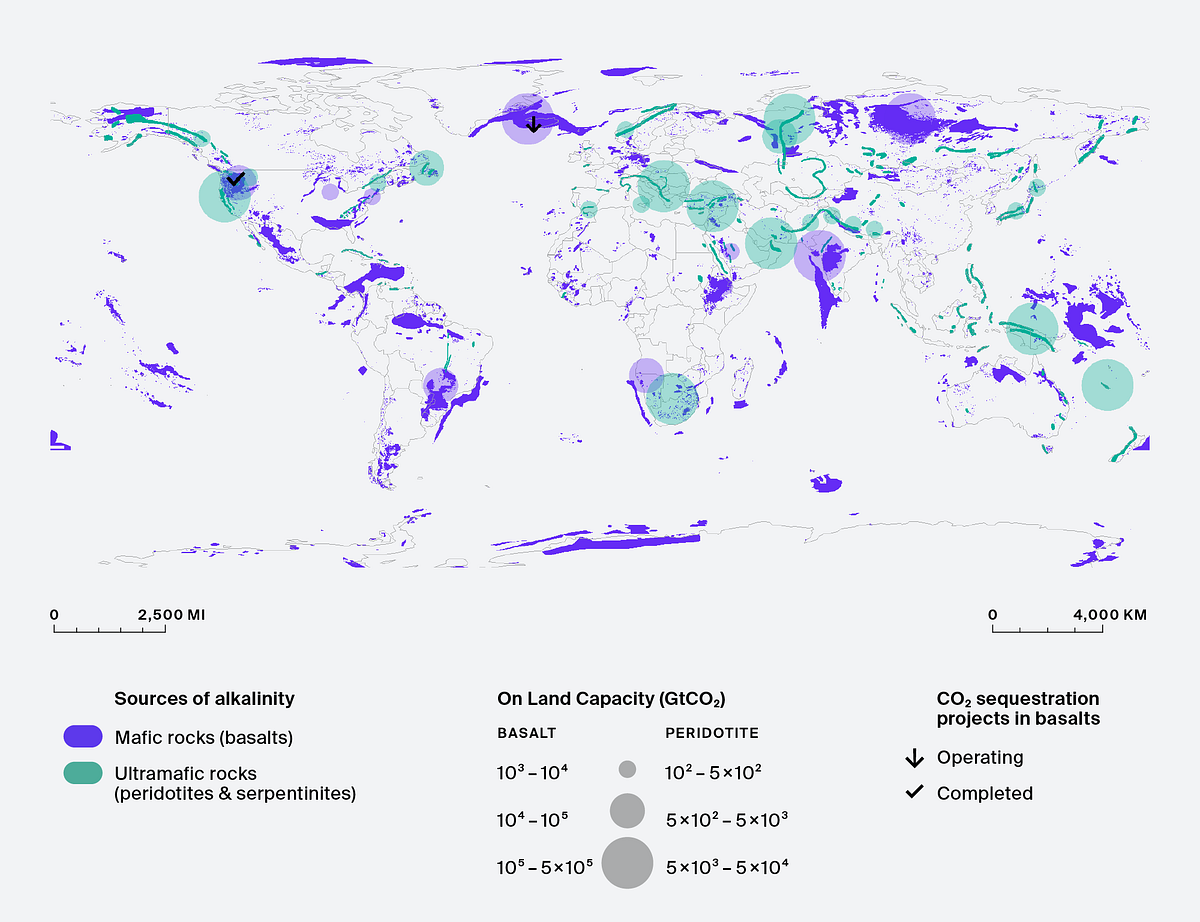

The map below shows the locations of mafic (basalts) and ultramafic (peridotites and serpentinites) with potential to sequester CO2. Large hotspots can be seen in Iceland, Indonesia, Saudi, West Coast USA, Russia, and South Africa.

This map does not include the large amount of basalt on the seafloor at mid ocean ridges and subduction zones, which could also be used to sequester carbon.

This figure demonstrates a cost-pricing estimate spread of the entire mineralisation space, indicating the range of error in projections for cost and storage potential in the size and position of the blocks of colour.

Within the AlliedOffsets database there are 23 total mineralisation projects that have been summarised in the Table 1. This is the current number of known mineralisation projects and their average price showcasing the a snapshot difference between the projected price in the previous figure and the state of the market now.

Puro.earth has also recently released their enhanced rock weathering methodology. There are currently no projects registered but it shows that the barrier to entry for enhanced rock weathering in terms of scientific rigour and industry support is quite low, enabling there to a larger development and uptake of projects in the coming years, compared to other CDR projects that are very far away from developing a cohesive methodology such as ocean alkalinity enhancement.

Overall, mineralisation is a potent CDR technology that holds great promise in fighting against climate change. Mineralization as a CDR technology is based on an accelerated carbonation and split into two subtypes of technology: in-situ mineralisation and ex-situ mineralisation.

In-situ mineralisation involves injecting CO2 into fluids deep within the earth, into ultramafic rocks where it then mineralises into calcite. This process can fully mineralise a rock deposit in approximately two years. The technology has the potential to be extremely cheap when strategically placed in locations that are ultramafic rock dense and are abundant in resources such as water and geothermal energy. It can be priced as cheaply as $30/tCO2 in ideal conditions. However, in-situ mineralisation needs large amounts of government funding and upfront investment for infrastructure. MRV is also an area that needs to be worked upon as the mineralisation process requires extensive geochemical analysis on fluids from within the Earth to achieve it.

Ex-situ mineralisation involves either the mechanical breakup of fresh new ultramafic rock or reuse of waste rock, such as basalt from mining activities, which are then taken, carbonated and either put into items such as concrete or stored deep in geological reservoirs. It takes 1.6t of fresh magnesium and iron rich rock to sequester 1tCO2 and mining that is extremely costly at a price of approximately $600/tCO2. Using waste rock from mining activities will drop this price to $50/tCO2 however there is very limited capacity for global waste rock, with at optimistic estimates only a potential of 1.3GtCO2/year able to be sequestered. Innovation needs to be made either technologically by decreasing mining cost of ultramafic rock or commercially by selling carbonated biproducts of the mineralisation process to other markets. This would enable the technology to drop the price low enough to be scalable.